Compare Models

Select maximum of 3 products to compare

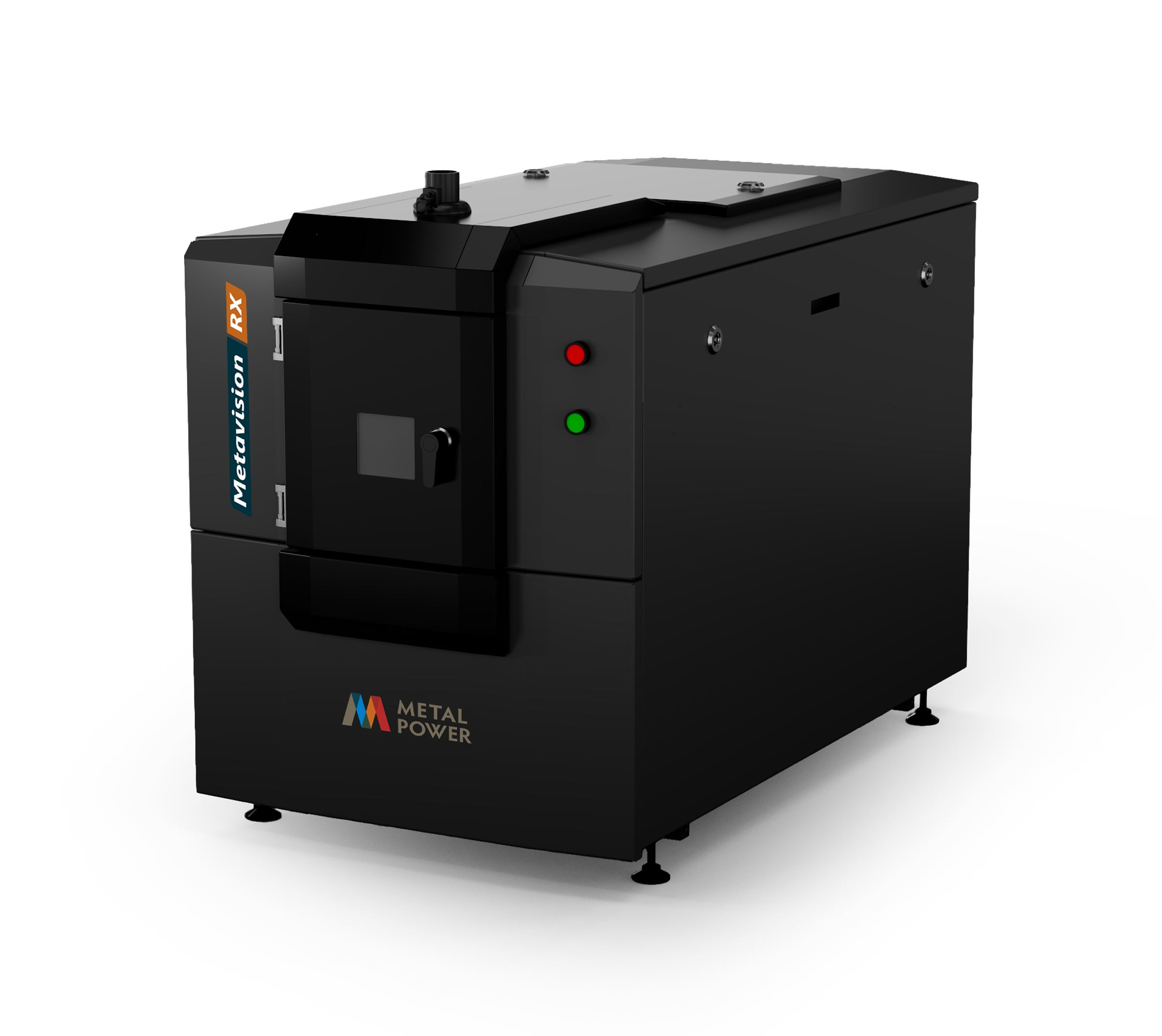

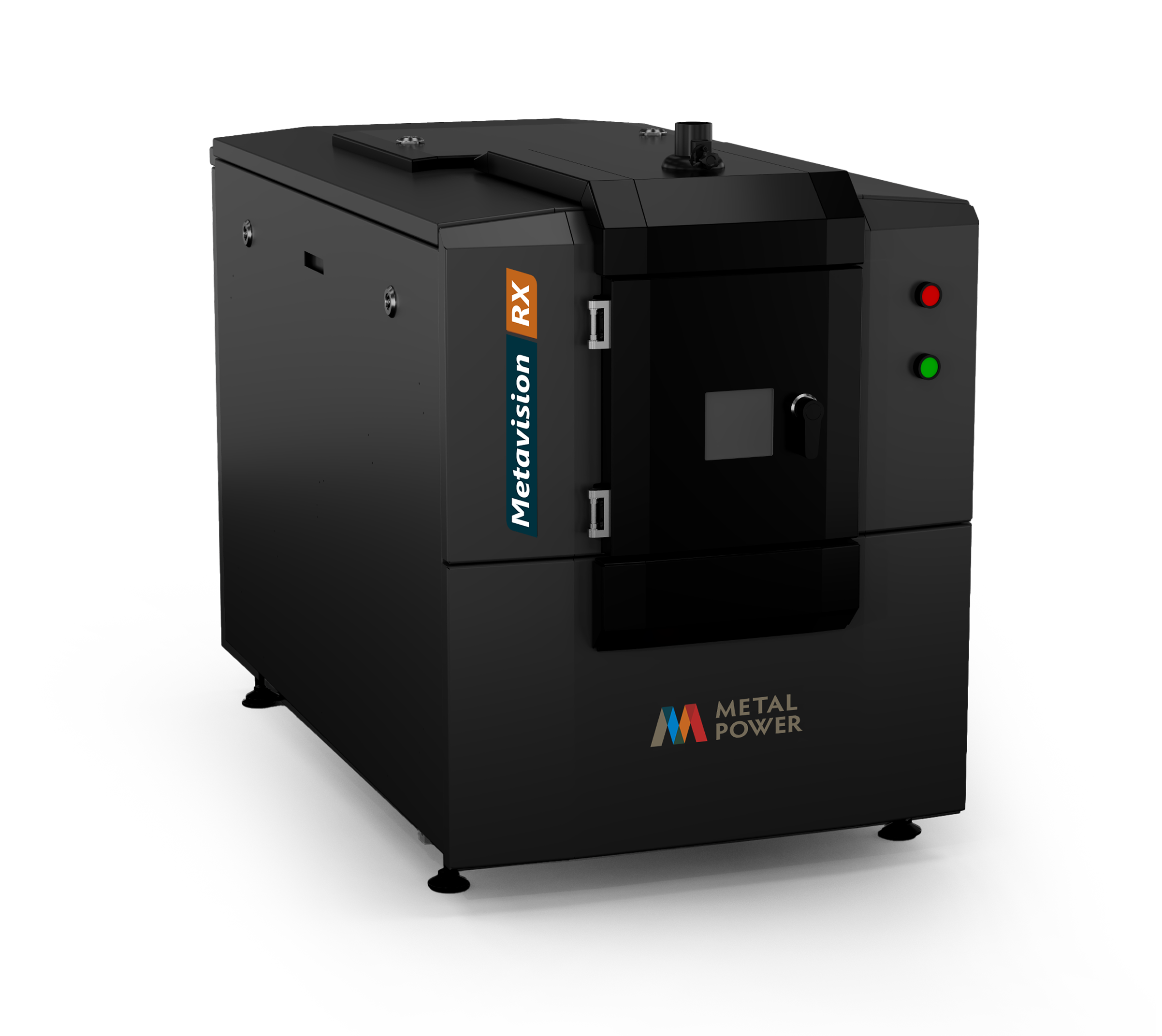

Metavision-RX: Extremely rugged oil analyser

Analyse 33 elements in under 30 seconds with sub-ppm limits for condition monitoring, with accurate insights into engine and machinery performance.

Highlights

Simultaneously analyse 33+ elements down to 0.1 ppm

Ultra-high-resolution CMOS optics

Compliant with ASTM D6595 and ASTM D6728 standards

Compliant with ASTM D5185 (ICP-AES) standard

165-800 nm spectral coverage with optional Sulphur analysis

Thermally stabilised optics to ensure high precision and stability

Focal length of up to 400 mm

Digital, current-controlled source for plasma generation

Features of Metavision-RX

Ecosystem

A comprehensive ecosystem for your Rotating Disc Electrode Optical Emission Spectrometer.

Tech Specs of Metavision-RX

Optics

Optics Configuration

Dual vacuum-free optics

Wavelength Coverage

165 to 800 nm

Element Coverage

33+ elements

Wear metals: AI, Cd, Cr, Cu, Fe, Pb, Mg, Mn, Mo, Ni, Ag, Sn, Ti, V, Zn

Contaminants: B, Ca, K, Si, Na

Additives: Ba, B, Ca, Cr, Cu, Mg, Mo, P, Si, Zn

Additional elements: As, Bi, Ce, Co, In, W, Zr, Be

Wear metals: AI, Cd, Cr, Cu, Fe, Pb, Mg, Mn, Mo, Ni, Ag, Sn, Ti, V, Zn

Contaminants: B, Ca, K, Si, Na

Additives: Ba, B, Ca, Cr, Cu, Mg, Mo, P, Si, Zn

Additional elements: As, Bi, Ce, Co, In, W, Zr, Be

Detector Type

CMOS

Resolution (RLD)

≤ 1 nm/mm

Grating (grooves/mm)

3,600 & 2,400

Applications

Applications

Determination of additives, wear metals and contaminants in lubricating oils, hydraulic fluids, gas turbine & diesel engine fuel, heavy fuel oil (HFO), crude oil, glycol coolants, etc.

Available Test Methods

ASTM D6595

ASTM D6728

ASTM D6728

Correlation To

ASTM D5185 (ICP-AES)

General

Source

Fully Digital PWM

Input Voltage & Frequency

90-270 VAC; 50/60 Hz

Argon Consumption

Advanced Argon saver (applicable for optional DUV Optics)

Size (Benchtop)

950 mm (L) × 540 mm (B) × 645 mm (H)

Weight (Benchtop)

≈ 80 Kgs

Consumables

Accessories

eSharp (electrode sharpener)

Starter Kit

Graphite discs (1000 pcs)

Graphite electrodes (100 pcs)

Sample cups (2 ml) (1000 pcs)

Graphite electrodes (100 pcs)

Sample cups (2 ml) (1000 pcs)

More Details

Reach out to us at marketing@metalpower.net to learn more about Metavision-RX and explore the detection of wear metals like Iron, Copper, and Aluminium, which indicate wear in engine components, to identify contaminants such as Silicon from dirt and Sodium from coolant leaks to ensure comprehensive monitoring of your engine and machine.

Looking to start a conversation? Fill the form to get a callback

Facing issues? Raise a ticket for speedy resolution

Get in touch

Thank you for sharing your request. We have successfully received your details, and our team will contact you within 24 hours to discuss your requirements.