Access your OES data anywhere and anytime with MPALabTab

MPALabTab is a powerful mobile application designed to provide secure, real-time access to OES test data across geographies and devices, enabling users to monitor, share, and analyse results on the go.

-

Access OES data anytime, anywhere

-

Cross-device synchronisation and data sharing

-

Enables remote monitoring and control

-

Secure cloud-based backup and retrieval

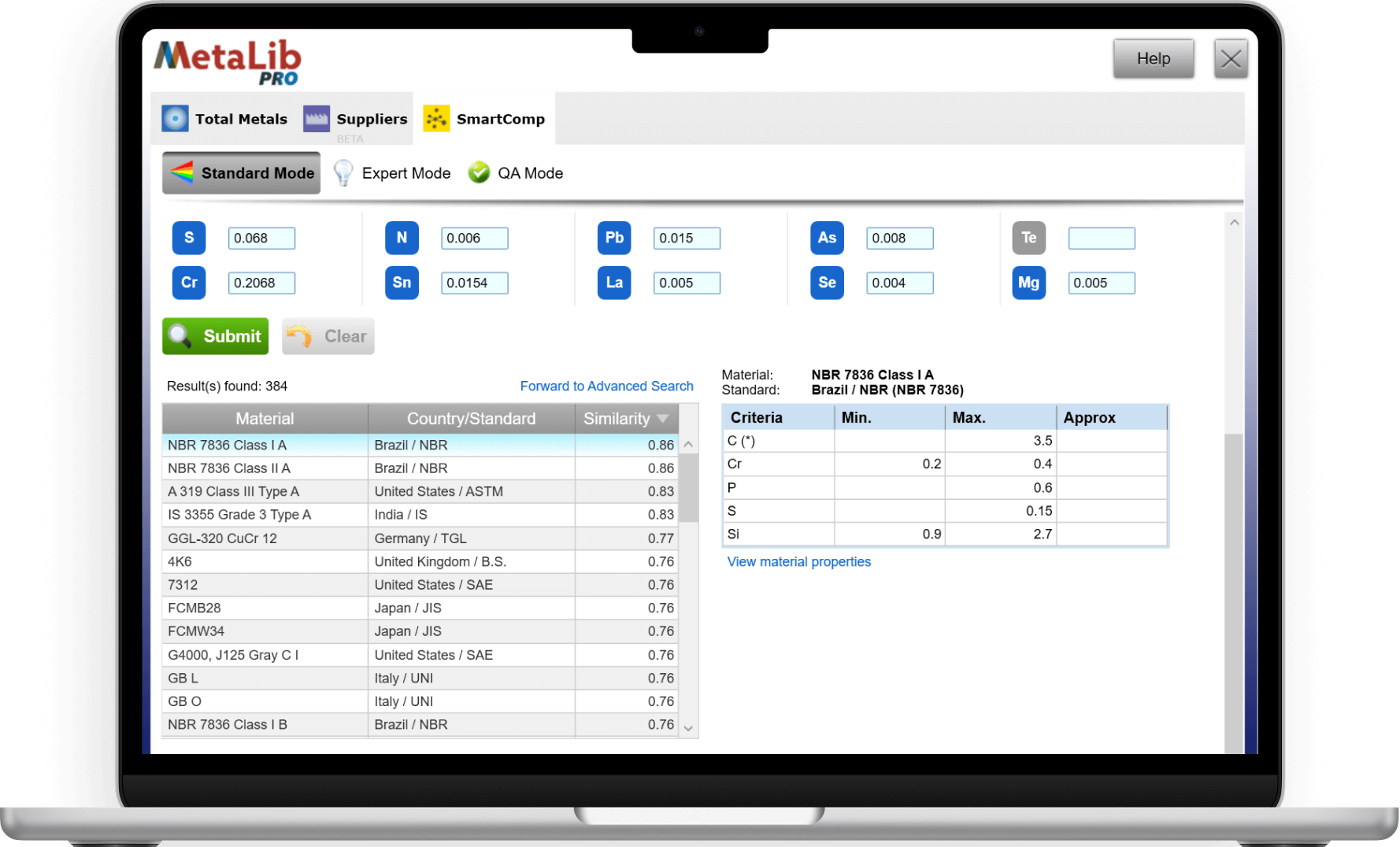

Access 350,000+ grades anytime with MetaLib Pro

A comprehensive grade identification library that enables instant verification and classification of metal samples based on spectral data, supporting over 350,000 global grades.

-

Largest database of international metal grades

-

Instant grade ID from spectral matches

-

Supports custom alloy library creation

-

Seamless integration with OES

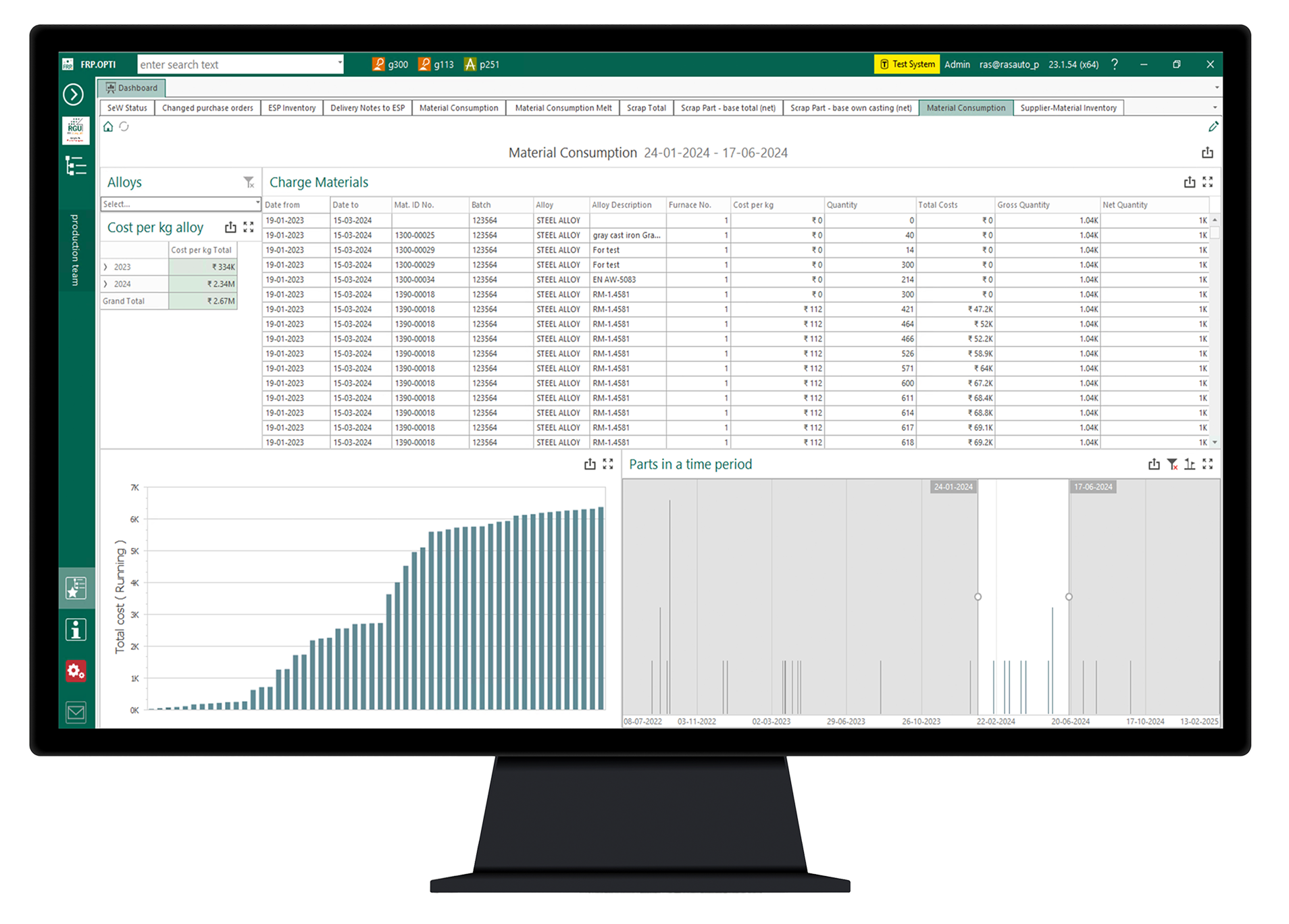

Streamline your lab workflows with [FP]-LIMS

Seamlessly integrate your lab processes with [FP]-LIMS from Fink & Partner, a Laboratory Information Management System that ensures real-time data capture, traceability, and efficient workflow management from sample receipt to result reporting.

-

Centralised data management for all analyses

-

Real-time syncing with analytical instruments

-

Customisable workflows for various lab needs

-

Enhanced compliance and traceability

![Lab workflows with [FP]-LIMS by Fink & Partner](https://www.metalpower.net/wp-content/uploads/2025/07/fp-lims.png)

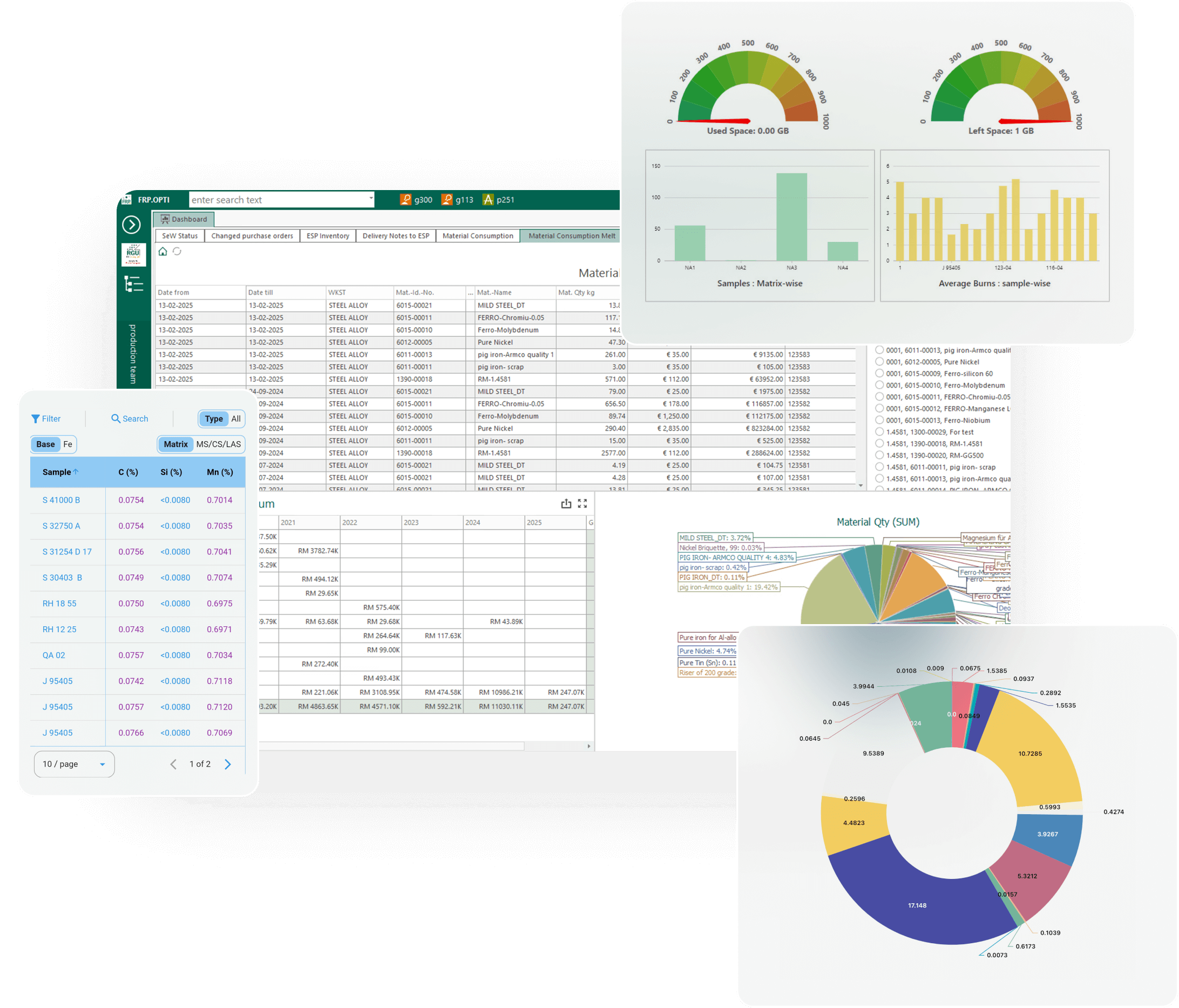

Reduce errors and material waste with FRP®.melt

FRP®.melt, a smart, automated solution for calculating the optimal metal charge mix, minimising material cost while ensuring the required composition is met with precision and speed.

-

Accurate melt cost optimisation

-

Reduced material wastage

-

Fast, real-time charge planning

-

Integration with spectrometer results