Compare Models

Select maximum of 3 products to compare

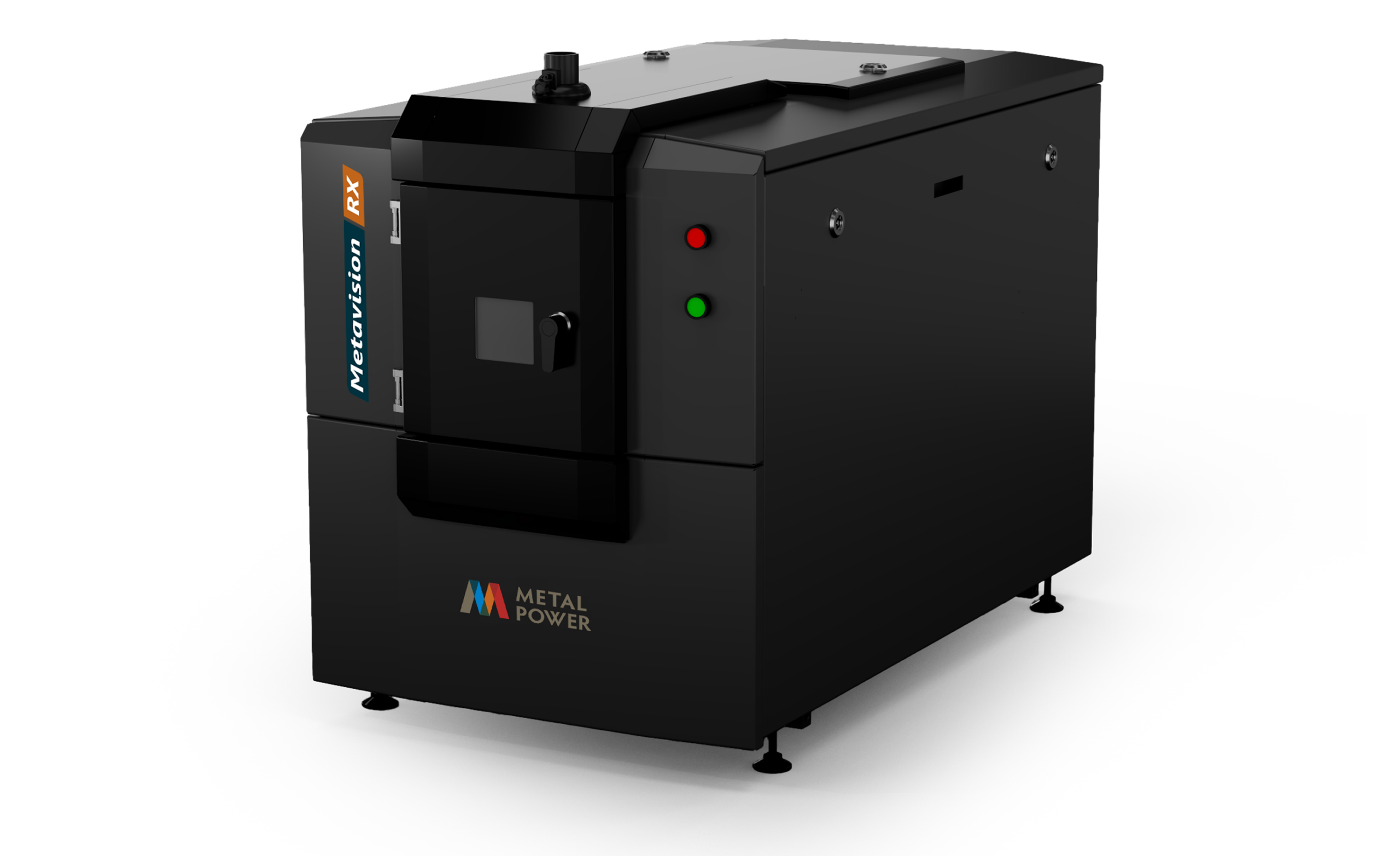

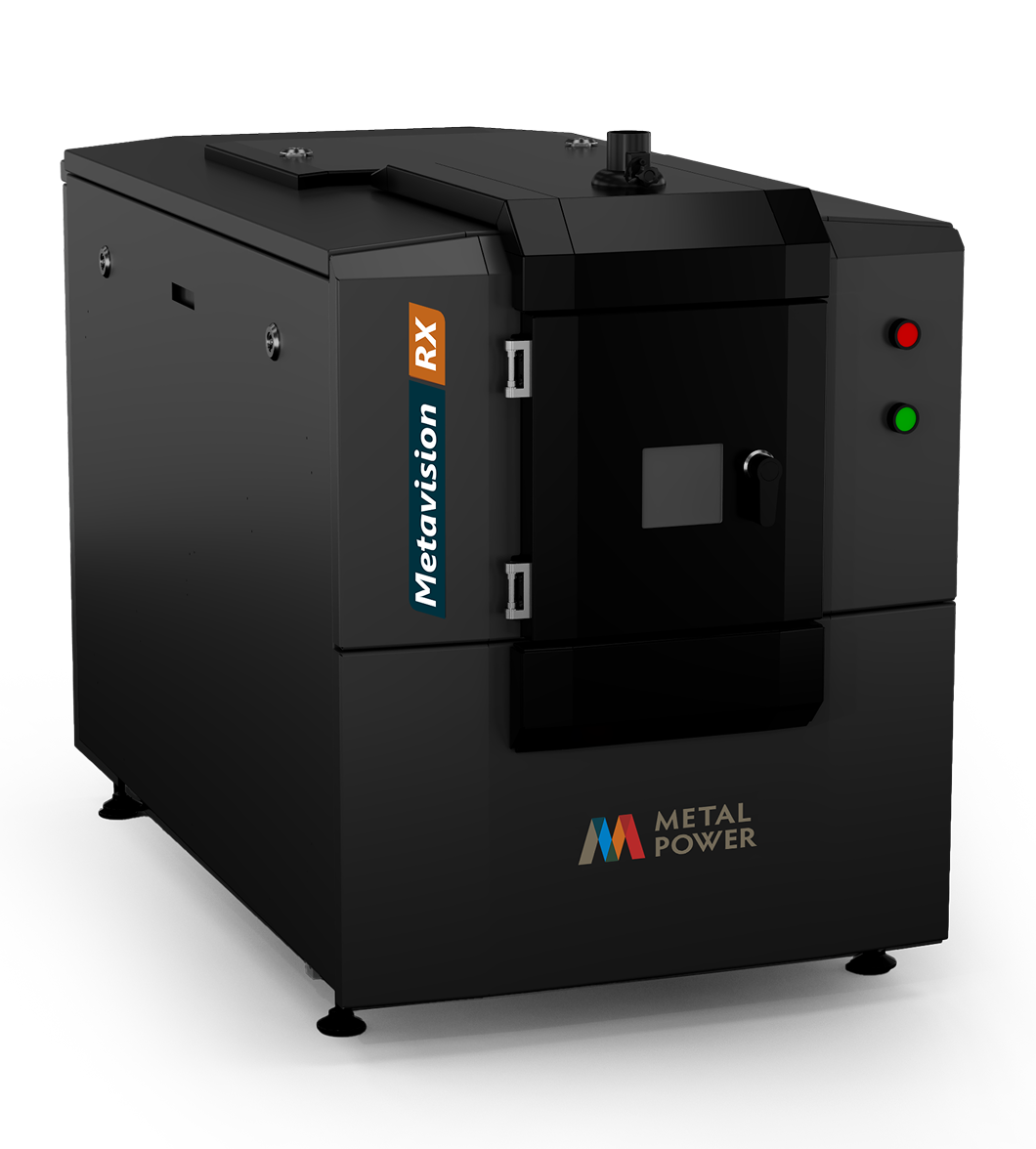

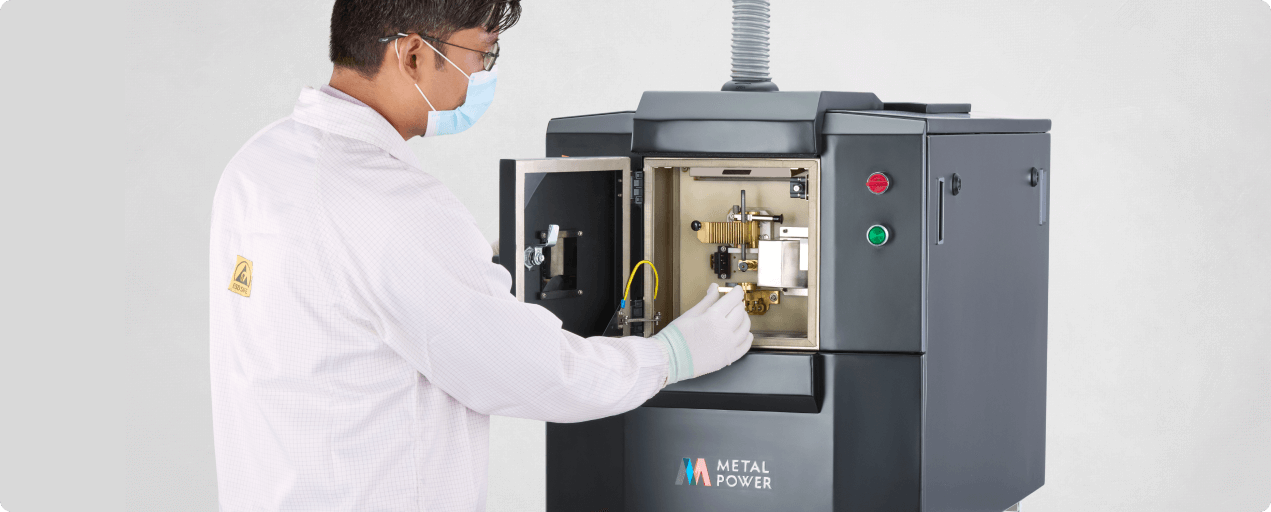

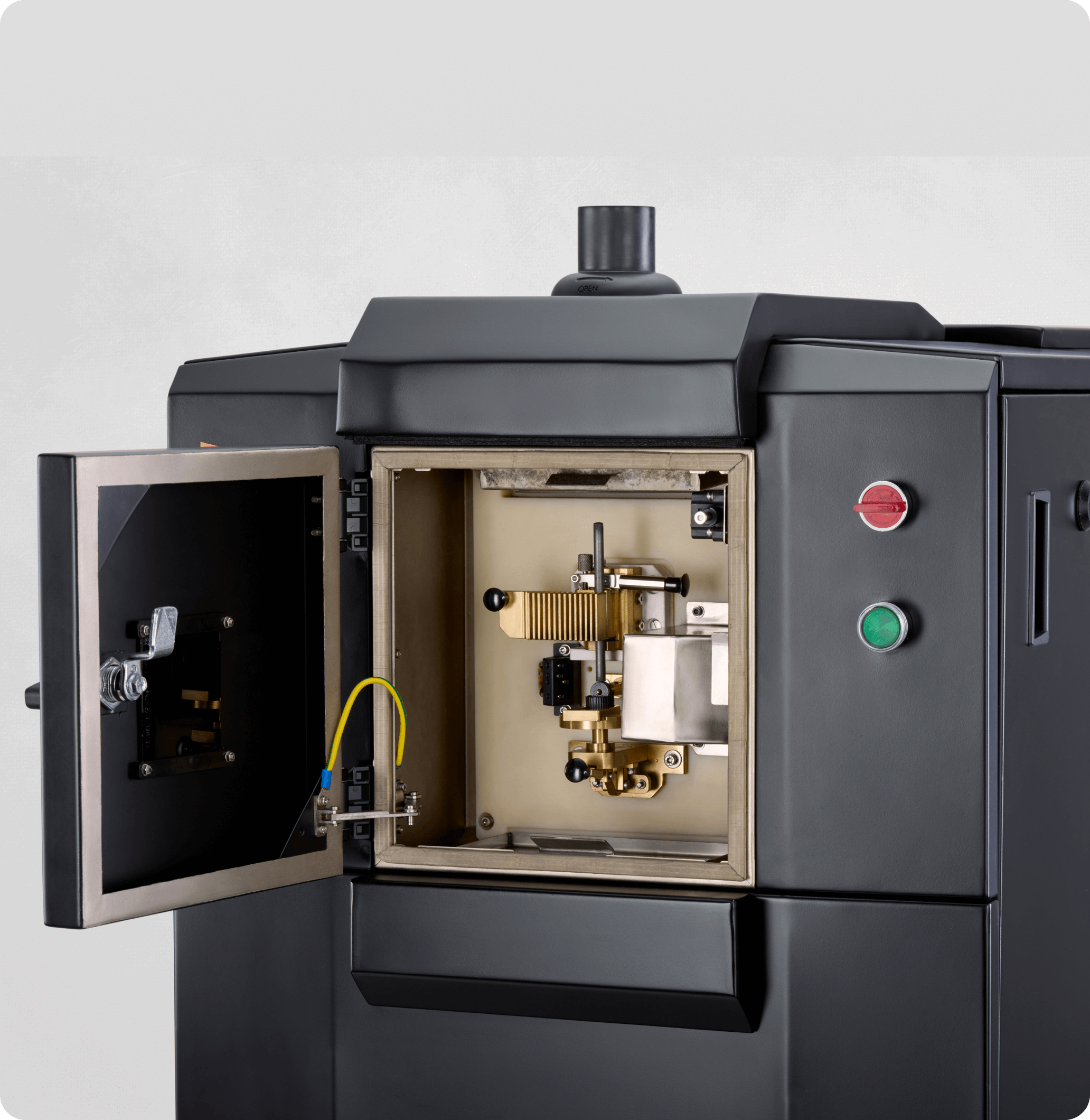

Explore Our RDE OES

Key

Highlights

Our RDE OES is used in oil analysis to detect and quantify metallic elements within oil. Among a multitude of applications, this is particularly useful for monitoring wear metals, contaminants, and additive elements.

Wide range of elements covered, simultaneously detecting 33 elements in under 30 seconds.

Sub-ppm detection limits down to 0.1 ppm with exceptional accuracy.

Compliant with ASTM D6595 & ASTM D6728 global standards, ensuring reliability and consistency.

Automatic Sensing Mechanism that enhances user convenience and operational safety.

When you need

RDE OES?

Oil analysis with an RDE OES is essential for condition monitoring. Industries such as automotive, power generation, manufacturing, mining, marine, aviation, and heavy equipment can significantly benefit from oil analysis. By proactively monitoring oil condition, businesses can make informed decisions, reduce risks, and enhance overall operational performance.

- Early Issue Detection – Identifies wear metals and contaminants for timely maintenance.

- Peak Efficiency – Monitors oil condition to keep machinery running optimally.

- Lower Maintenance Costs – Prevents major damage, saving on repairs and extending equipment life.

- Regulatory Support – Aids compliance with standards through documented condition reports.

- Higher Uptime – Boosts equipment reliability and minimises downtime.

Get in touch

Thank you for sharing your request. We have successfully received your details, and our team will contact you within 24 hours to discuss your requirements.