Client Overview:

A leading manufacturing conglomerate supplying advanced materials and components to India’s defence and strategic mobility sectors initiated a next-generation amphibious vehicle project. The mission called for the use of high-strength stainless steels and aerospace-grade titanium alloys. Given the criticality of applications, extremely tight compositional tolerances had to be met, especially for gaseous and interstitial elements.

Analytical Challenges:

-

Dual-base requirement:

Accurate elemental analysis of both ferrous and titanium materials under a single platform.

-

Gaseous element precision:

Ultra-low detection for Nitrogen (N), Oxygen (O) in both bases, and Hydrogen (H) in Titanium—vital for weld integrity and material toughness.

-

Compliance with ASTM standards:

Results had to conform to ASTM E1086 for steels and ASTM E2994 for titanium alloys.

-

Low maintenance, high uptime:

Deployment in a secure facility meant minimal service access—reliability was non-negotiable.

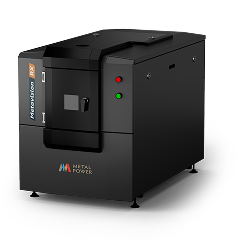

MPA’s Technical Solution: Metavision-1008i3 Optical Emission Spectrometer

To meet the above demands, Metal Power Analytical supplied its Metavision-1008i3, an advanced multi-base spectrometer equipped with dual-optics and multi-CMOS detectors, optimised for high-accuracy, low-ppm elemental detection.

Application-Specific Calibrations Provided:

- Steels: Austenitic, martensitic and duplex stainless steels (per ASTM E1086)

- Titanium Alloys: Ti-6Al-4V, Ti Grade 2, and Ti-5Al-2.5Sn, critical in aerospace, defence, and marine use

Each calibration was tailored with tight control ranges and validated reference standards. Below are representative control limits for selected critical elements in titanium alloys per ASTM E2994:

Grade Spotlight: Ti-6Al-4V (Grade 5) – Critical Element Limits

Element |

Spec Limit |

Metavision-1008i3 Detection Limit (ppm) |

Oxygen (O) |

Max 0.20% | ~10 ppm |

Nitrogen (N) |

Max 0.05% | ~8 ppm |

Hydrogen (H)* |

Max 0.015% | ~10 ppm |

Aluminium (Al) |

5.5 – 6.75% | ~1 ppm |

Vanadium (V) |

3.5 – 4.5% | ~1 ppm |

Iron (Fe) |

Max 0.40% | ~5 ppm |

Carbon (C) |

Max 0.08% | ~20 ppm |

* Hydrogen analysis is not covered in ASTM E2994 but is available through in-house validated calibration on the Metavision-1008i3.

Performance Outcomes:

-

Gaseous Element Mastery:

The Metavision-1008i3 successfully delivered low-ppm detection of O, N, and H, key to ensuring fatigue resistance and weld performance in Ti alloys.

-

Exceptional Stability:

The peltier-cooled optics and advanced detectors ensured drift-free analysis, even in a high production environment.

-

Future-Proof Platform:

Multi-base capability with on-site matrix additions enabled flexibility for future alloy development and trace element inclusion.

Why It Matters:

In strategic manufacturing—where materials may undergo high stress, thermal cycling, and harsh environments—the role of interstitial gases like oxygen, nitrogen, and hydrogen cannot be overstated. Even minor deviations in these elements can lead to embrittlement, cracking, or catastrophic failures. By deploying the Metavision-1008i3, the client not only met but exceeded the quality benchmarks laid out in ASTM E2994 and E1086, reinforcing India’s self-reliance in advanced defence technologies.