Client Profile

The client is the foundry division of one of India’s leading automotive manufacturers, producing critical Cast Iron and SG/Ductile Iron castings for both passenger and commercial vehicle lines. The foundry also manages the analysis of alloy steels, covering both incoming raw materials and vendor-supplied end-use parts.

This division operates at a scale where every casting matters — both in terms of quality and in keeping the production lines moving without interruption.

Client Requirement

The client needed an Optical Emission Spectrometer (OES) that could:

- Deliver absolute accuracy across Cast Iron, SG/Ductile Iron, and steels.

- Reliably measure Nitrogen, especially in SG Iron and steels, to ensure casting integrity.

- Operate 24×7 without compromise, keeping pace with production demands.

- Maximise productivity and uptime, since any delay in the lab directly slows down the foundry’s output.

Challenges Faced

Despite a highly skilled team and robust processes, the foundry faced three recurring challenges:

-

Wide grade coverage

– testing multiple bases meant the OES had to handle complex transitions from steel to CI/SG iron without losing accuracy where low carbon and high carbon can create memory effects.

-

Nitrogen requirement

– precision at single-digit ppm levels was critical, but most systems struggled in production settings.

-

Downtime & maintenance

– in a continuous production environment, time lost in recalibration, chamber cleaning, or system stabilization had a direct impact on productivity.

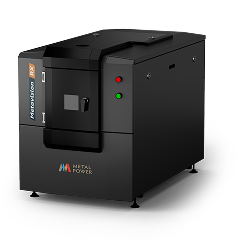

The Metal Power Analytical Solution

Metal Power deployed the Metavision-1008i3, configured to address each of these needs directly:

- Complete ferrous base programs covering all Cast Irons and steels of interest.

- Nitrogen detection down to 8 ppm, ensuring mechanical and metallurgical standards were consistently met.

- Single-sample Smart Standardization, which slashed recalibration time from 30 minutes to just 5 minutes.

A New Design Philosophy: Spark Chamber + Optics

What made the real difference was the newly engineered spark chamber combined with hermetically sealed optics and an internal multi-stage argon purification system for the optics, a design built not just for accuracy, but for enhanced productivity and stability, offering rapid stabilization and an ultra-pure optics environment.

Inbuilt Argon Repurification

- Ensures removal of oxygen, moisture, and hydrocarbons.

- Keeps Argon in the DUV optics sealed and repurified to ~99.9999% purity.

- Guarantees short stabilisation times and unshakable optical stability — even in continuous 24×7 use.

Spark Chamber Advantages

- 40% higher plasma stability for consistent results.

- 30% reduction in soot, with automatic soot removal reducing maintenance/cleaning frequency.

- 180° clamp rotation for rapid sample changes.

- Quick-release screws for rapid change of base plate and quicker cleaning of the spark chamber.

- Accommodates all sample sizes and shapes (required for their scrap analysis), improving workflow flexibility.

Operator Ergonomics & Maintenance

- Integrated diagnostics tool that monitors system health and flags issues before they affect performance.

- Single-sample SmartSTD allows for recalibration within just 5 minutes.

- Minimal tool requirement and fast consumable changes.

- 30% less downtime for servicing, on account of modular access.

Outcome & Benefits

Since installation, the Metavision-1008i3 has been running non-stop, 24×7, enabling the foundry to achieve unmatched productivity with new SmartSTD single-sample standardisations, minimal downtime, and uninterrupted testing. It has delivered confidence in Nitrogen results, which is critical for SG Iron and steels, while ensuring exceptional optical stability through its hermetically sealed and Peltier-cooled low temperature optics. Operators also benefit from a far more user-friendly experience with the latest Analyst 10.0 software that includes predictive diagnostics.

Together, these factors have resulted in smooth production alignment, eliminating bottlenecks between the lab and the shop floor.

Before vs After: Impact at a Glance

Aspect

|

Before

|

After Metavision-1008i3

|

Standardisation time

|

~30 minutes, multi-sample | 5 minutes, single sample |

Soot cleaning |

Frequent manual cleaning | 30% reduction + automatic soot removal |

Productivity |

Interrupted runs | Seamless 24×7 operation |

Conclusion

By combining top-end analytical performance with a radically redesigned spark chamber and advanced optical system, the Metavision-1008i3 gave the foundry the tools it needed to balance quality, speed, and productivity. The system turned the lab into a true enabler of production — ensuring that castings meet the highest standards while keeping output uninterrupted.

This case demonstrates how a thoughtful blend of technology and design philosophy can solve not just technical problems, but also the larger business challenge of maintaining continuous operations in a high-pressure automotive environment.