Pure Copper & Alloy Testing

Copper: Testing Requirements

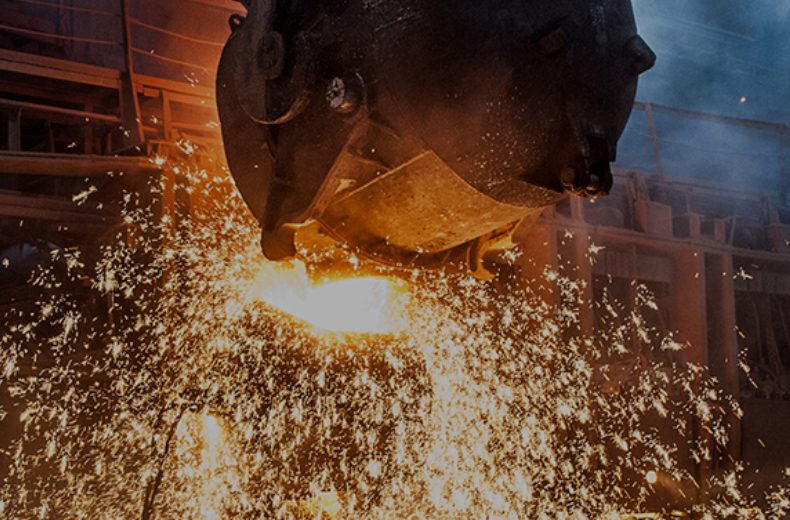

The Copper industry encompasses a vast range of applications, from pure grades like OFE (Oxygen-Free Electronic), OFC (Oxygen-Free Copper), and ETP (Electrolytic Tough Pitch) to high-alloy compositions such as Brass and Cupro-Nickel. The elemental analysis of Copper, whether for purity or alloy optimisation, demands high-accuracy instruments that can ensure compliance with stringent industry standards and drive cost efficiencies. Optical Emission Spectrometers for Copper are the cornerstone of analytical excellence for these requirements.

Pure Copper: ETP, OFC, and OFE

Pure Copper grades are defined by their high levels of purity, typically 99.90% or more. However, specific grades like ETP, OFC, and OFE have distinct elemental requirements, particularly concerning Oxygen analysis in Copper, which makes testing even more challenging.

Critical Oxygen Requirements

Oxygen is a key determinant of Copper grade classification:

- OFE & OFC: ≤10 ppm O (with some grades as low as 5 ppm)

- ETP: 200-400 ppm O (with some grades as low as 50 ppm or higher ranges)

For manufacturers, detecting Oxygen accurately is crucial to meet grade specifications and ensure product reliability. Advanced Optical Emission Spectrometers for Copper testing enable low detection limits, ensuring accurate and precise measurement for both major and trace elements.

Stringent Impurity Limits

Purity requirements for Copper are often more demanding than they appear. For instance, even though allowable limits for trace elements like Bismuth, Selenium, and Tellurium may be listed as 2 ppm, 2 ppm, and 1 ppm, their combined total often cannot exceed 3 ppm. Similarly, combined impurity limits may be far lower than the sum of individual ‘max’ values.

A high-resolution Optical Emission Spectrometer for Copper testing is essential to accurately measure over 30 elements with single or sub-ppm detection limits.

Copper Alloys: Critical Testing Needs

For Copper alloy makers, ensuring the correct balance of alloying elements like Zinc, Nickel, and Lead is key to meeting product specifications. Alloy manufacturers aim to stay as close as possible to the minimum specified concentrations of these elements to reduce material costs without compromising on quality.

Role of OES in Alloy Testing

An OES for Copper alloy testing provides:

-

Accurate Elemental Analysis:

Determines the precise concentration of alloying and trace elements in the melt.

-

Process Optimization:

Enables real-time adjustments by analysing molten samples, avoiding re-melting or rejections.

-

Cost Efficiency:

Reduces safety margins for alloying elements, optimising raw material usage while maintaining quality.

The ability to analyse samples within seconds allows manufacturers to make informed decisions during production, ensuring compliance with stringent specifications and minimising waste.

Metal Power OES for the Copper Industry

Metal Power Analytical offers the world’s most comprehensive range of Optical Emission Spectrometers for Copper, designed to cater to every application and budget within the Copper industry.

High-End Solutions for Ultra-Pure Copper

The Metavision-10008X and Metavision-1008i3 are tailored for manufacturers focused on high-purity applications:

-

Metavision-10008X:

Ideal for OFE Copper, offering sub-ppm detection for Oxygen (1 ppm) and critical elements like Bi, Se, and Te. Suitable for purity levels up to 99.998% and beyond.

-

Metavision-1008i3:

Best for OFC and ETP Copper, offering Oxygen detection limits of 10 ppm and comprehensive analysis for purity levels of 99.992%+.

Economical Models for Alloy Makers

For alloy manufacturers, the Metavision-8i delivers exceptional performance for a competitive budget. These models are well-suited for analysing Brass, Bronze, and other Copper alloys.

Entry-Level Models for Budget-Conscious Applications

The MOSS is the most compact and economical spectrometer in the world. Capable of analysing 21 elements in Copper, including Ag, Cd, Cr, and Be, MOSS is ideal for small-scale manufacturers and budget-conscious operations.

Mobile Solutions for On-Site Testing

For tasks like PMI (Positive Material Identification), scrap sorting, and entry-gate inspections, Metal Power Analytical offers the Metavision-MX+ and Metavision-MX. These mobile spectrometer solutions come with a range of probes—arc, spark, UV, and combined options—ensuring reliable testing in the most challenging environments.

Unique Metal Power Solutions for Copper Testing

Fine Wire Analysis

Metal Power Analytical’s patented technology enables quantitative analysis of Copper wires as thin as 0.1 mm in diameter, meeting the stringent requirements of the Copper industry.

Foil Analysis

With the ability to analyse Copper foils down to 20 microns (0.02 mm) in thickness, Metal Power Analytical delivers unmatched value for applications requiring precision in thin materials.

Direct-Base Analysis

Unlike traditional OES models that calculate base element concentration indirectly, Metal Power Analytical OES directly analyses Copper, eliminating potential inaccuracies in base element assessment.

Master Alloy Testing

Metal Power Analytical offers customised solutions for analysing master alloys with extremely high alloying element concentrations. This ensures better process control, accurate pricing, and reliable vendor quality evaluations.

Partner with Metal Power for Copper Alloy Testing

With cutting-edge technology, patented solutions, and industry-leading expertise, Metal Power Analytical is your trusted partner for Copper alloy testing and Oxygen analysis in Copper. Our Optical Emission Spectrometers for Copper are designed to meet the diverse needs of the industry, ensuring precision, reliability, and cost efficiency.

For more details, contact us at marketing@metalpower.net.