Client Overview:

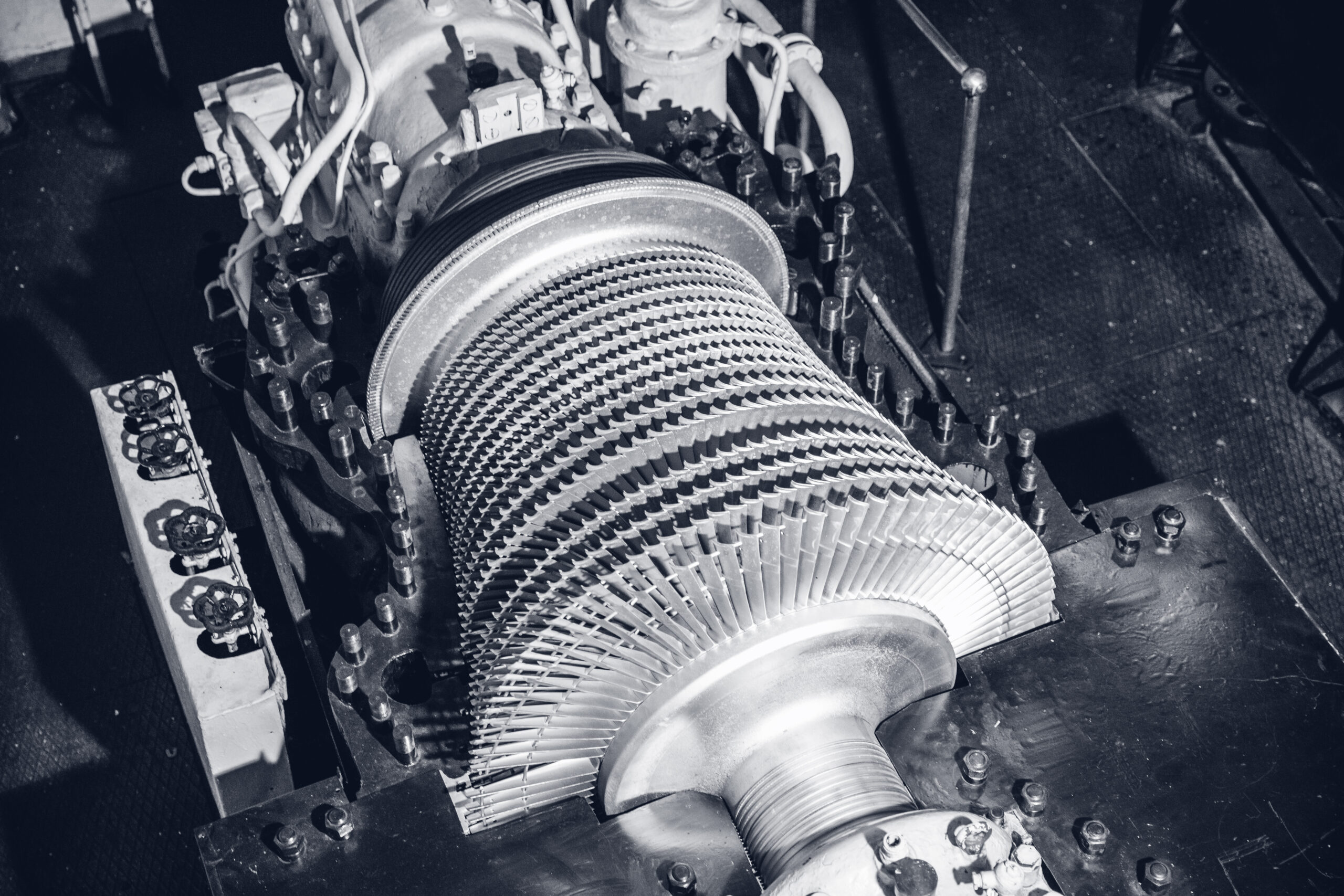

A leading public-sector engineering enterprise involved in the manufacture of complex, high-precision industrial equipment for power, defence, transportation, and process industries. The client’s operations include fabrication and assembly of critical components such as turbines, compressors, and high-pressure systems, requiring stringent material control.

Client Requirement:

The client sought a robust mobile elemental analysis solution capable of:

- Conducting positive material identification (PMI) and quantitative elemental analysis of Carbon Steel, Alloy Steel, Stainless Steel, and Copper Alloys.

- Testing components on the shop floor, open yards, and assembly lines, beyond traditional lab environments.

- Analysing critical UV-range elements—Carbon (C), Sulphur (S), Phosphorus (P), Nitrogen (N), and Boron (B)—which are essential for mechanical integrity and corrosion resistance in mission-critical applications.

- Delivering rapid and accurate results (within 10–15 seconds) for elements such as Cr, Mo, Ti, V, Ni, Mn, Co, W, Cu, Si, Ag, Cd, Sn, Sb, Pb, Bi, etc., in Fe- and Cu-base alloys.

- Accommodating irregular sample geometries, such as turbine blades and impellers, with potential to scale to additional alloy bases like Co, Al, Ti, Ni, and Sn in the future.

Unique Challenge:

The client’s manufacturing workflow involved handling heavy, large, and geometrically complex components, many of which could not be transported to a central lab. They faced the following key challenges:

- Inability of traditional lab spectrometers to access testing points on large or curved components

- Need for flexibility in analysing non-standard surfaces without affecting measurement accuracy

- Requirement for field-deployable ruggedness and minimal downtime in high-throughput production environments

- Future-proofing to accommodate other alloy bases and evolving production demands

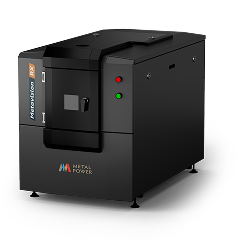

MPA’s Solution – Metavision-MX+ Mobile OES with UVis Smart Probe:

To meet these exacting technical needs, Metal Power Analytical (MPA) supplied the Metavision-MX+, equipped as follows:

UVis Smart Probe

- Delivered complete elemental coverage, including UV-range elements, in a single-spark, single-probe design

- Eliminated the need for switching hardware, thereby increasing speed and reducing human error

- Delivered high accuracy and repeatability across varied ferrous and non-ferrous matrices

Customised Sample Adaptors

- Supplied with a full range of standard adaptors

- Enhanced with two specially designed custom adaptors to allow secure and consistent testing on curved and complex surfaces like steam/gas turbine blades and compressor impellers

High-Speed Performance

- Enabled analysis of full elemental range within 12 seconds, supporting rapid decision-making

- Provided accurate results for trace-level elements essential for mechanical properties and failure prevention

8-Hour Portable Operation

- Battery-powered system offering full-shift operation without dependence on external power

- Ideal for on-site inspection, outdoor testing, and remote quality audits

Scalability and Future Expansion

- Multi-CMOS based system architecture allowed for easy addition of new alloy bases (Co, Al, Ti, Ni, Sn) without hardware changes, ensuring long-term ROI and flexibility