Compare Models

Select maximum of 3 products to compare

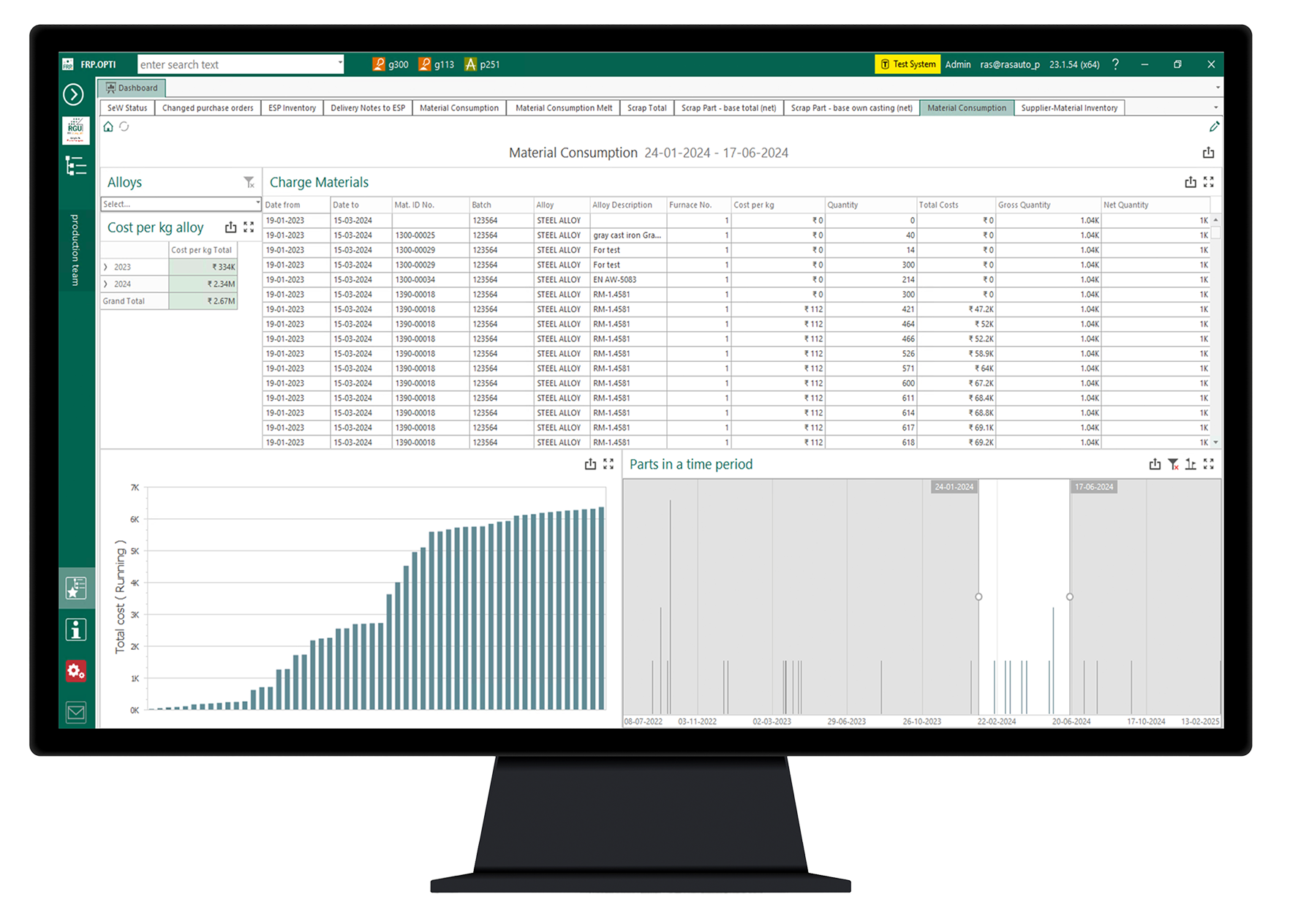

FRP®.melt: Achieve Smarter Melts at Lower Costs

FRP®.melt, a sophisticated charge optimisation/correction platform designed for end-to-end melt planning. It ensures accurate cost forecasting, optimal resource use, and better furnace productivity, while supporting full traceability and digital process integration.

FRP®.melt Features

End-to-End Melt Planning

Manage every stage of melting and treatment up to ready-to-pour batches, ensuring consistency and repeatability.

Energy Cost Reduction

Supports energy management at peak consumption points, helping reduce energy per tonne and overall cost.

Comprehensive Traceability

Maintains a complete audit trail of all charge steps, compositions, consumption, and analytical results for each batch.

Furnace-Side Process Control

Integrates with foundry systems to display process instructions, analyser data, and furnace parameters at the melt site.

Cost-Effective Mix Optimisation

Calculates material requirements while factoring in returns, alloys, and base metals to minimise cost.

Smarter Recharging & Resource Use

Reduces material waste and overuse by dynamically adjusting the charge make-up based on actual requirements.

Get in touch

Thank you for sharing your request. We have successfully received your details, and our team will contact you within 24 hours to discuss your requirements.